The Extra smooth finish has its strong points such as a high-quality surface similar to injection molding and the sealing against liquid and gas. However, there are also a few limitations that we want to inform you about in order to check the feasibility of your project and achieve the best possible result for your part.

Technical specifications

-

Maximum part dimensions

PA12 (SLS) 560 x 330 x 360 mm

PA12 (MJF) 360 x 274 x 375 mm

Ultrasint TPU 90A-01 (MJF) 360 x 274 x 375 mm - Standard accuracy: printing accuracy not guaranteed after this finish, no guarantee for matching of parts of an assembly after this finish

- Minimum wall thickness: 2 mm, even wall thicknesses recommended (no significant variations of wall thicknesses)

- Interlocking or enclosed parts? : No

-

Hollowing of Ultrasint TPU 90A-01 (MJF) parts: No

Preparation before production – please upload instructions

Parts need to be hung up for this finishing process. Please provide instructions about the A-side of your part. See the article: What do I upload as instruction for Extra Smooth finish?

Process related variations

Please note that variations in smoothness of processed parts and variations in color, specifically in case of the dark MJF parts, are part of this treatment process and must be expected.

Design features with risks

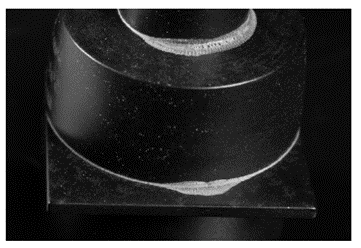

Corners can lead to accumulation of treatment product / powder remains and cause ‘bridging’:

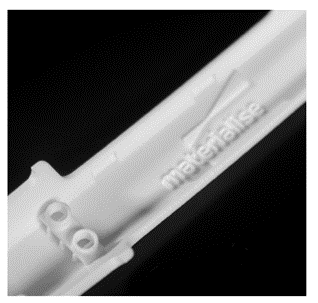

We recommend using embossed surface labelling (see right picture below) because engraved surface details are susceptible to bridging (see left picture below):

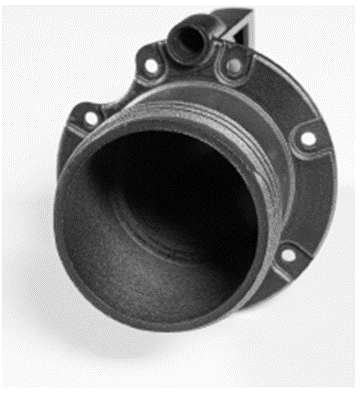

Cavities, insides of tubes, internal channels have inner surfaces which tend to be less smooth:

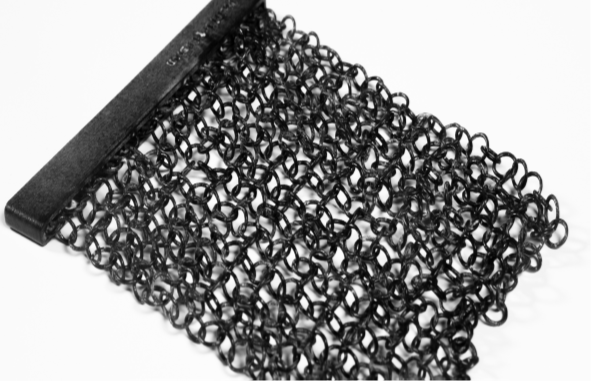

Interlocking parts will stick together after the process: