Contrary to popular belief, there isn’t a one-size-fits-all approach to 3D printing resolution. In 3D printing, resolution refers to the horizontal (or X-Y resolution) and vertical resolution (Z-resolution or layer thickness). And it’s the Z-dimension that makes it 3D printing.

When thinking about printing resolution, you are probably trying to find out how detailed and accurate your 3D-printed part will be. While the Z-axis resolution (layer thickness) values can easily be consulted, they are less related to printing quality. Therefore, you should actually look at minimum detail size and accuracy of a 3D printing material.

The reason why you can’t choose printing resolution is because the layer thickness, minimum detail size, and accuracy is specific to each 3D printing technology. Layer thickness is related to minimum detail but they don’t both share the same value e.g. the layer thickness of Polyamide ranges from 0.1 to 0.12 but its minimum detail size is 0.3 mm.

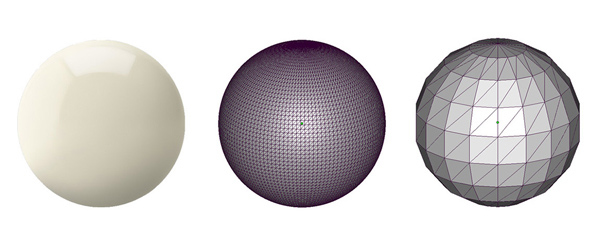

Please take note that resolution also plays a part when creating a 3D file. In most CAD software, when exporting a file (for instance to STL) you will be asked to define the tolerance for the export. This tolerance is defined as the maximum distance between the original shape and the STL mesh you are exporting. We advise choosing 0.01 mm for a good export. Exporting with a tolerance smaller than 0.01 mm does not make sense because most 3D printers cannot print at this level of detail and your file will be unnecessarily large.

For example, the globe on the left is in its native file format from CAD software; the one in the middle is a high-resolution STL export; and the one on the right is a low-resolution STL export.